This document presents research on the phase composition and structural parameters of aluminum nitride thin films produced via magnetron sputtering.

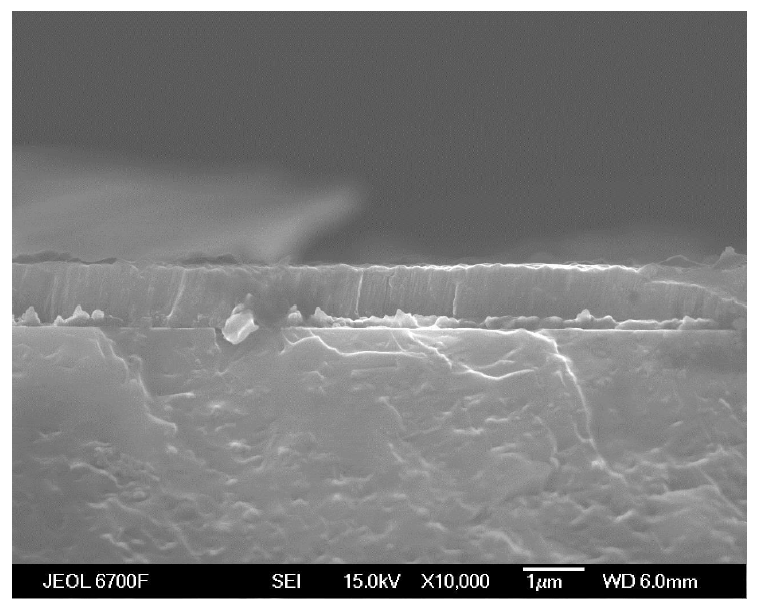

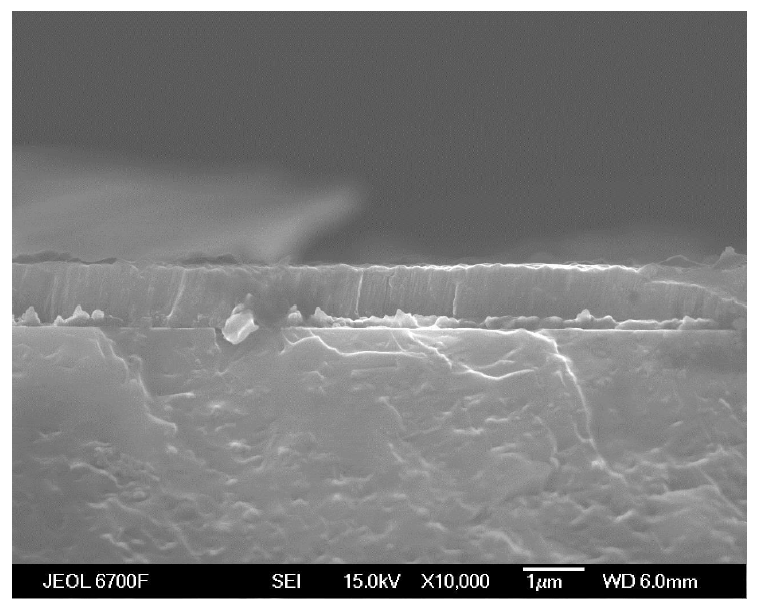

Fig. 1. SEM image of the surface of a thin AlN films.

Fig. 2. SEM image of the chip texture of the AlN film.

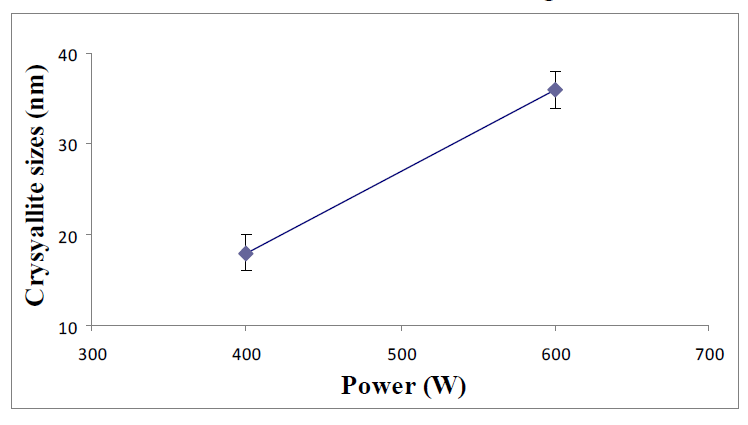

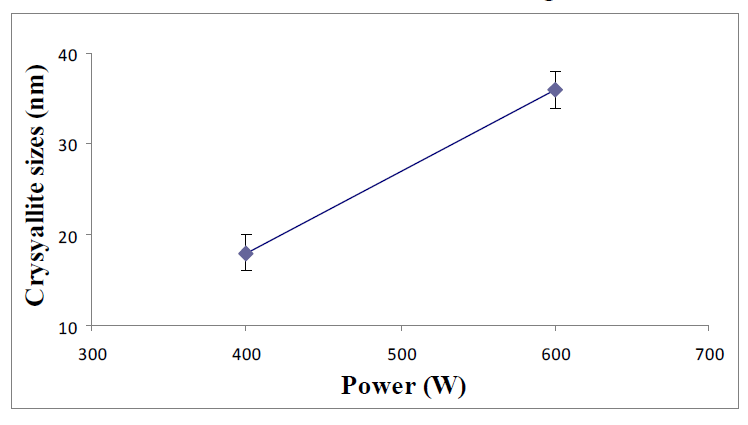

Fig. 3. Dependence of crystallite sizes on the magnetron discharge power (0.07Pa, 300°C).

Fig. 4. Dependence of crystallite sizes on the magnetron discharge power (0.07Pa, 350°C).

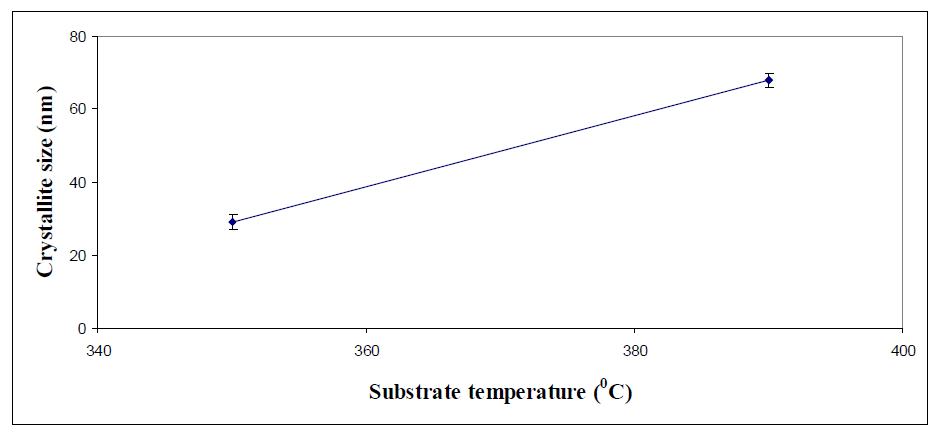

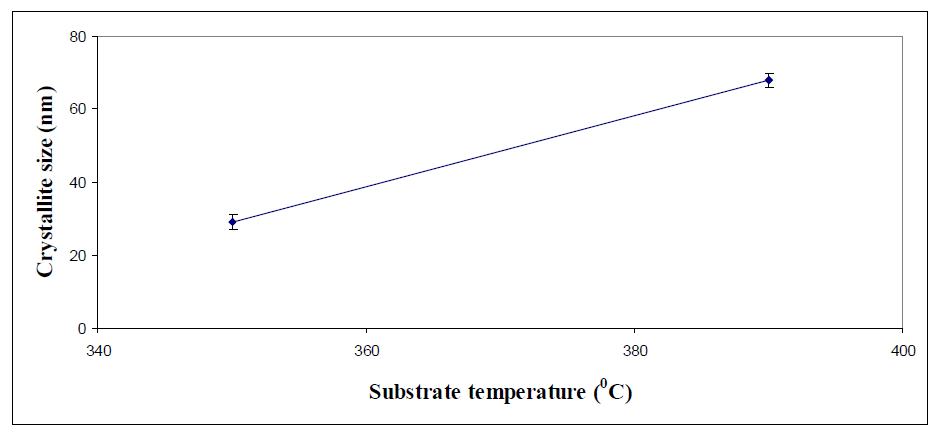

Fig. 5. Dependence of the crystallite sizes on the substrate temperature (0.07Pa, 600W, Ar/N2=4/5).

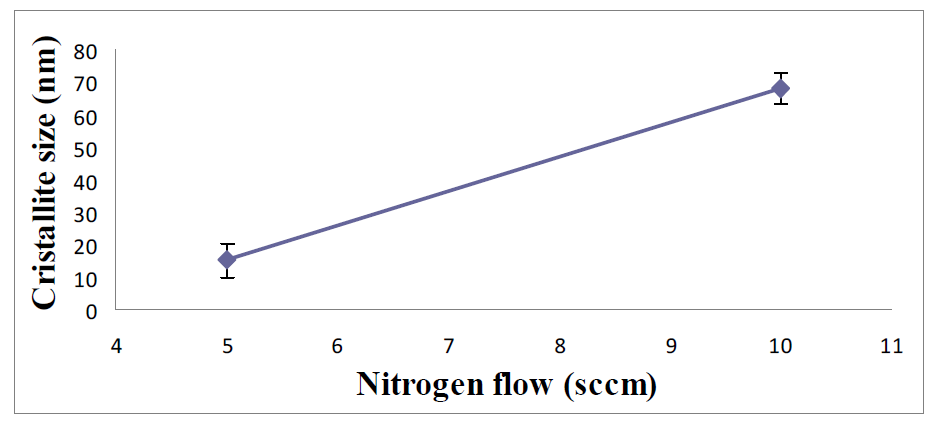

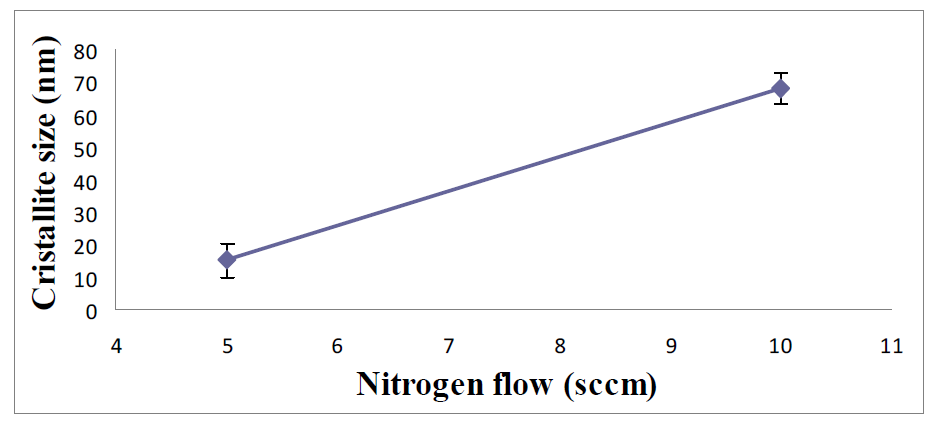

Fig. 6. Dependence of crystallite sizes on nitrogen flow (0.1Pa, 700W, 390°C).

Introduction

-

Aluminum nitride (AlN) thin films are increasingly utilized in microelectronics due to their favorable physical properties, particularly as piezoelectric materials in surface acoustic wave (SAW) devices and MEMS technologies.

Various methods exist for producing AlN films, including chemical vapor deposition and molecular beam epitaxy, but magnetron sputtering is favored for its low-temperature and cost-effective nature.

The quality of AlN films is influenced by deposition parameters, necessitating research to understand their effects on structural and morphological properties.

Experimental Procedure

-

The study investigates the impact of magnetron discharge power, substrate temperature, and gas flow ratios on the structural and phase composition of AlN films.

Substrates undergo chemical treatment before deposition, and films are characterized using X-ray diffraction and scanning electron microscopy.

Key technological parameters include variations in pressure, power, substrate temperature, and gas flow rates.

Results

-

The research reveals that all studied coatings exhibit both X-ray amorphous and crystalline phases, with crystallinity varying from 10% to 91%.

Lattice parameters are consistent with known values for AlN films, and a cubic structure is observed in some samples.

The relative microdeformation of the lattice ranges from 0.7·10^-3 to 6.9·10^-3, with crystallite sizes decreasing as microdeformation increases.

The predominant orientation of grains is along the (002) axis, indicating a hexagonal structure, with some samples also showing (111) orientation.

Impact of Deposition Parameters

-

Discharge Power: Increasing power from 400W to 900W results in larger crystallite sizes, but exceeding 900W deteriorates film texture due to increased surface damage.

Substrate Temperature: Higher substrate temperatures lead to increased crystallite sizes and improved crystallinity due to enhanced atomic mobility.

Nitrogen Flow: Increasing nitrogen flow in the gas mixture correlates with larger crystallite sizes, attributed to reduced sputtering rates and slower film growth.

Conclusions

-

The study concludes that the surface morphology and texture of AlN films are significantly influenced by discharge power, substrate temperature, and gas composition.

Optimal conditions for achieving high-quality films with a smooth surface and strong c-axis orientation are critical for effective application in microelectronic devices.

Further research is planned to refine deposition parameters to enhance the quality of AlN films for better performance in acoustic wave devices.

Acknowledgment

-

The research was funded by a grant from the Russian Science Foundation and utilized equipment from the Tomsk Regional Core Shared Research Facilities Center at Tomsk State University.

Figures

Fig. 1. SEM image of the surface of a thin AlN films.

Fig. 2. SEM image of the chip texture of the AlN film.

Fig. 3. Dependence of crystallite sizes on the magnetron discharge power (0.07Pa, 300°C).

Fig. 4. Dependence of crystallite sizes on the magnetron discharge power (0.07Pa, 350°C).

Fig. 5. Dependence of the crystallite sizes on the substrate temperature (0.07Pa, 600W, Ar/N2=4/5).

Fig. 6. Dependence of crystallite sizes on nitrogen flow (0.1Pa, 700W, 390°C).